How Does a Mini Batching Plant Work?

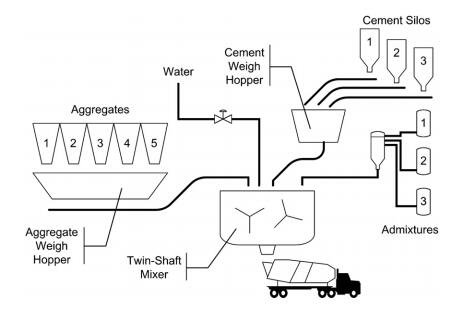

As we all know, mini batching plant is a construction equipment to produce concrete. However, do you know how does a Mini Batching Plant work? At this moment, we haomei machinery will talk about how does a Mini Batching Plant concrete batch plant work with our users. Generally, concrete batching plant can achieve the four functions of storing, conveying, batching and mixing. After measuring, aggregate are discharged to a hopper by belt conveyor. Cement and fly ash are transported by screw conveyor to measure in measuring bucket. Water and additives are pumped and metered in pump and metering bucket. After the measurement of various materials, all materials are mixed in concrete mixer. After finish mixing, open discharge door, concrete can be used to many concrete construction projects.

After all, how does a mini batching plant work? It should include the following stages:

Stage of raw material preparation

The raw material preparation stage includes the following process: Aggregate, cement and other admixtures are put into cement silo to store.

Stage of raw material metering

Start mixing plant and set the required production of concrete raw material formulations to operate the mini batching plant.

Concrete Batching Machine for Sale

Stage of raw material transportation

After weighing, aggregate hopper door is closed. Opening discharging gate and discharging aggregates to the running flat belt conveyor. The flat belt conveyor will transfer aggregates to the inclined belt conveyor, and the inclined belt conveyor will transfer aggregates into aggregate hopper.

Stage of raw material unloading

After water and admixture are weighed, and admixture metering bucket is discharging by pneumatic butterfly valve, and then the admixture enter into the water metering bucket. The aggregate, water, cement and admixture are finally discharged into the diesel engine concrete mixer according to the sequence of operation.

Stage of mixing

The concrete mixer will mix the raw materials until it get the desired concrete mixing time accordance with the computer control system. The concrete mixer adopts advanced technology, and it has the advantages of event mixing, quick speed and high efficiency.

Stage of finished material discharge

After complete mixing, open discharging gate and put the finished concrete into concrete mixer truck. In addition, the discharging time machine can be adjusted according to usage. Unloading the material in the mixer, and users can enter the next working cycle when the discharging gate is closed.

Contact Us

Now, do you know how does a mini batching plant work? If you still have any question, consult we, and haomei machinery will reply timely. Of course, if you have needs for Mini concrete batching plant, concrete pump, Mini concrete mixer, concrete mixer pump, dry mortar plant, construction lift and other products, call we haomei machinery and we will keep 24 hours contact. Welcome your coming and visiting, and we hope that we can meet each other next time. If you have many interest in our company, factory and products, email or call we haomei machinery.