Good mixing quality

Mini Batching Plant adopts compulsory concrete mixer, and it can mix various kinds of concrete violently,

Environmental protection.

There is a dust-proof equipment on the top of the cement silo, and it prevents the powder leakage.

Easy operation.

The materials can be conveyed by hopper, and it costs less manpower and time.

Mini Concrete Batch Plant for Sale

Mini Batching Plant has simple structure and low investment, which is the ideal choice for small-sized construction projects or personal projects. Besides, it is easy to transport mini concrete plant, so it is quite suitable for the users who often transfer the projects. Mainly, Mini Batching Plant consists of material conveyor, concrete mixer and batching machine. And HZS25, HZS35, HZS50 concrete batching plant are the common type. And concrete mixer mainly adopts JS750, JS1000 compulsory twin shaft concrete mixer, which is also the first choice rural concrete batching plant due to its simple structure and easy operation. With high quality, stable performance, timely transportation, haomei mini batching plant for sale deserves your purchase.

We provide Mini Batching Plant on well-defined parameters of quality such as Strength, Capacity, and Functionality. We have a team of excellent professionals involved in meeting high demands of our valuable clients.

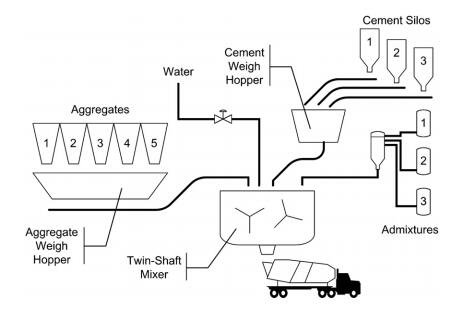

Working Flows of Mini Batching Plant

When it comes into operation, the discharging door is driven by the air cylinder, and the aggregates drop in each weighing hopper. When it reaches the preset value, the door will close automatically. After weighing, the aggregates will be discharged in the hopper, and storage hopper will go to the highest position and discharge the aggregates in to mixers.

The powders were conveyed from the cement silo to the weighing hopper by the screw conveyor. When it reaches the preset value of Mini Batching Plant , the screw conveyor will stop running and feeding.

Water and additive are conveyed to its weighing hopper by water pump and additive pump, respectively. When it reaches the preset value, it will stop conveying. After weighing, mix the additive into water, which ensures that the additive distributes evenly in the concrete.

Put the aggregates, cement, fly ash, water and additive into the concrete mixer?sequentially, and then convey the concrete into the concrete mixing truck.